Quality Commitment

At Ittefaq Electrotech, we are dedicated to delivering PCBs that meet the highest industry standards. Our commitment to quality is embedded in every stage of our manufacturing process, ensuring precision, durability, and reliability.

What Sets Our Quality Apart?

- Strict Quality Control Measures – Every PCB undergoes multiple inspection stages, including Automated Optical Inspection (AOI) and Electrical Testing.

- High-Grade Materials – We use premium-quality raw materials to enhance performance and longevity.

- Advanced Testing Procedures – From bare board testing to functional verification, we leave no room for defects.

- Continuous Improvement – We constantly innovate and refine our processes to exceed customer expectations.

- State-of-the-Art Manufacturing – Our facility is equipped with the latest PCB fabrication and assembly technologies.

- Precision Engineering – We ensure accurate layer alignment, fine-pitch components, and high-density routing for flawless functionality.

- Environmental Responsibility – We follow eco-friendly practices, including lead-free soldering and waste management.

- Customer-Centric Approach – We work closely with our clients to ensure their unique design specifications are met.

- End-to-End Quality Assurance – From prototyping to mass production, we maintain the highest quality at every stage.

At Ittefaq Electrotech, quality isn't just a process—it’s our promise.

Quality Control

Our goal are high-quality products and satisfied clients; therefore, quality control is an important part of our production process.

Quality assurance is implemented in every aspect, including:

File Review Before Production

At Ittefaq Electrotech, we conduct a thorough PCB file review before production to eliminate errors and ensure manufacturability. Our Design for Manufacturability (DFM) check optimizes the process, reducing defects and improving efficiency. We validate Gerber files, drill placements, trace widths, and component footprints to meet industry standards. Our team also checks board outlines, stack-up integrity, and panelization for maximum quality. With Design Rule Checks (DRC) and Electrical Rule Checks (ERC), we prevent common design errors. A detailed pre-production review helps us minimize delays, reduce risks, and ensure flawless manufacturing—because quality starts with precision.

Raw Materials Guarantee

At Ittefaq Electrotech, we use only high-grade raw materials to ensure durability, reliability, and optimal performance in every PCB we manufacture. We source premium-quality copper-clad laminates, high-TG substrates, and lead-free solder masks to meet IPC, ISO, and RoHS compliance standards. Our materials undergo strict quality inspections to ensure they meet electrical, thermal, and mechanical performance requirements. By maintaining a rigorous material selection process, we guarantee superior conductivity, enhanced durability, and long-lasting performance for your PCBs—because quality starts at the core.

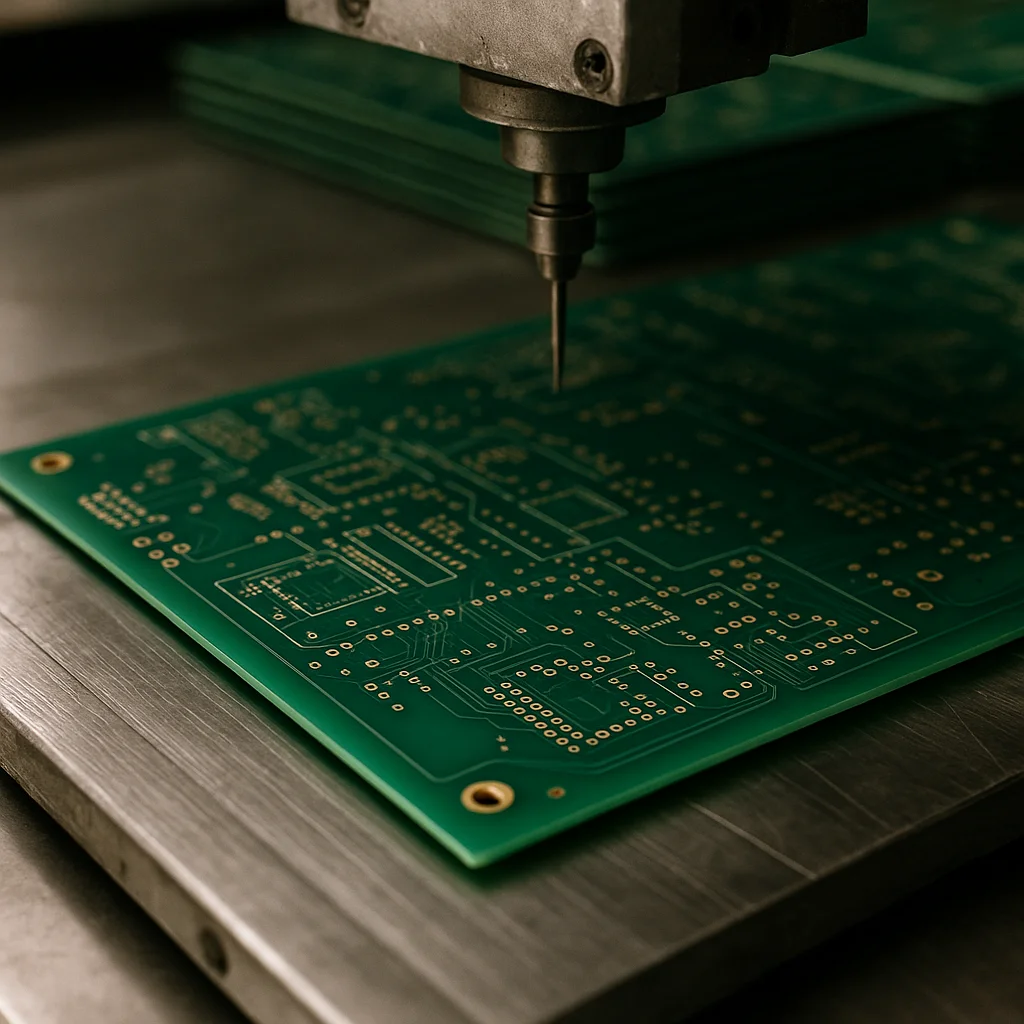

Advanced Equipment

At Ittefaq Electrotech, we utilize state-of-the-art manufacturing and testing equipment to ensure precision, consistency, and high-quality PCB production. Our facility is equipped with automated drilling, high-precision CNC machines, laser direct imaging (LDI), and advanced solder mask application systems for superior accuracy. We also employ Automated Optical Inspection (AOI), X-ray inspection, and in-circuit testing (ICT) to detect defects and ensure flawless functionality. By investing in cutting-edge technology, we enhance production efficiency, maintain strict quality control, and deliver high-performance PCBs that meet global industry standards.

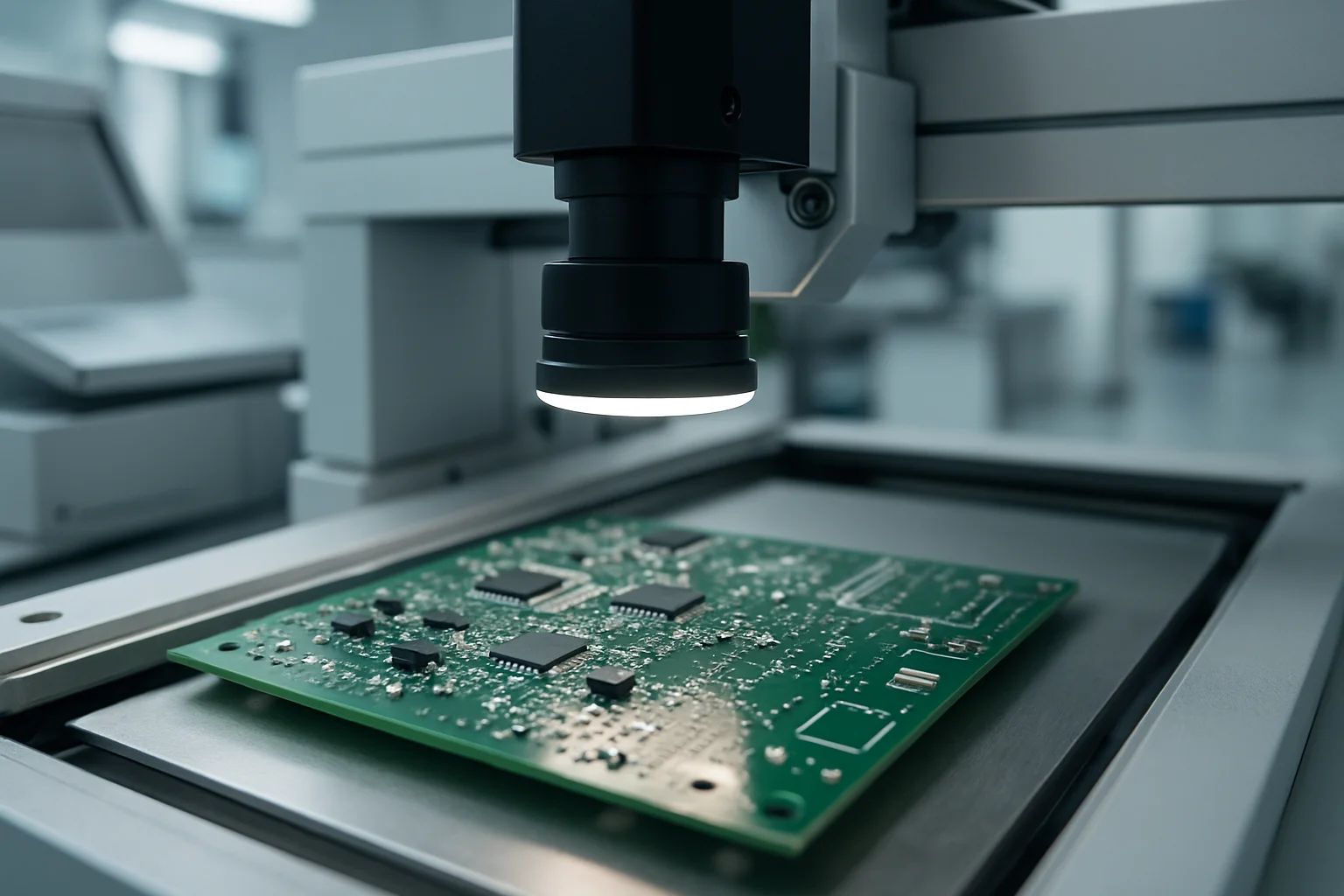

Multiple Testing Before Shipping

At Ittefaq Electrotech, we ensure that every PCB undergoes rigorous testing before it reaches our customers. Our multi-stage inspection process guarantees flawless functionality and reliability in real-world applications. We conduct Automated Optical Inspection (AOI), Electrical Testing (E-Test), X-ray inspection, and Functional Testing to detect short circuits, open circuits, misalignments, and other defects. Each board is verified against design specifications and industry standards to ensure top-tier performance. With our comprehensive testing protocols, we eliminate failures, enhance durability, and deliver high-quality PCBs—because precision matters.

Strict Management

Strict management in PCB manufacturing at Ittefaq Electrotech ensures high-quality, reliable products through a disciplined approach at every stage of production. We start with rigorous design reviews to ensure accuracy, followed by careful selection and inspection of materials to meet the highest standards. Our precision manufacturing processes, coupled with automated machines and advanced technology, guarantee consistency. Throughout production, we conduct regular quality control checks, including visual and electrical inspections, to detect and resolve issues early. Real-time monitoring helps optimize operations, and final inspections ensure that each PCB meets customer requirements before delivery. This thorough management process allows us to consistently deliver top-tier, precise PCBs.