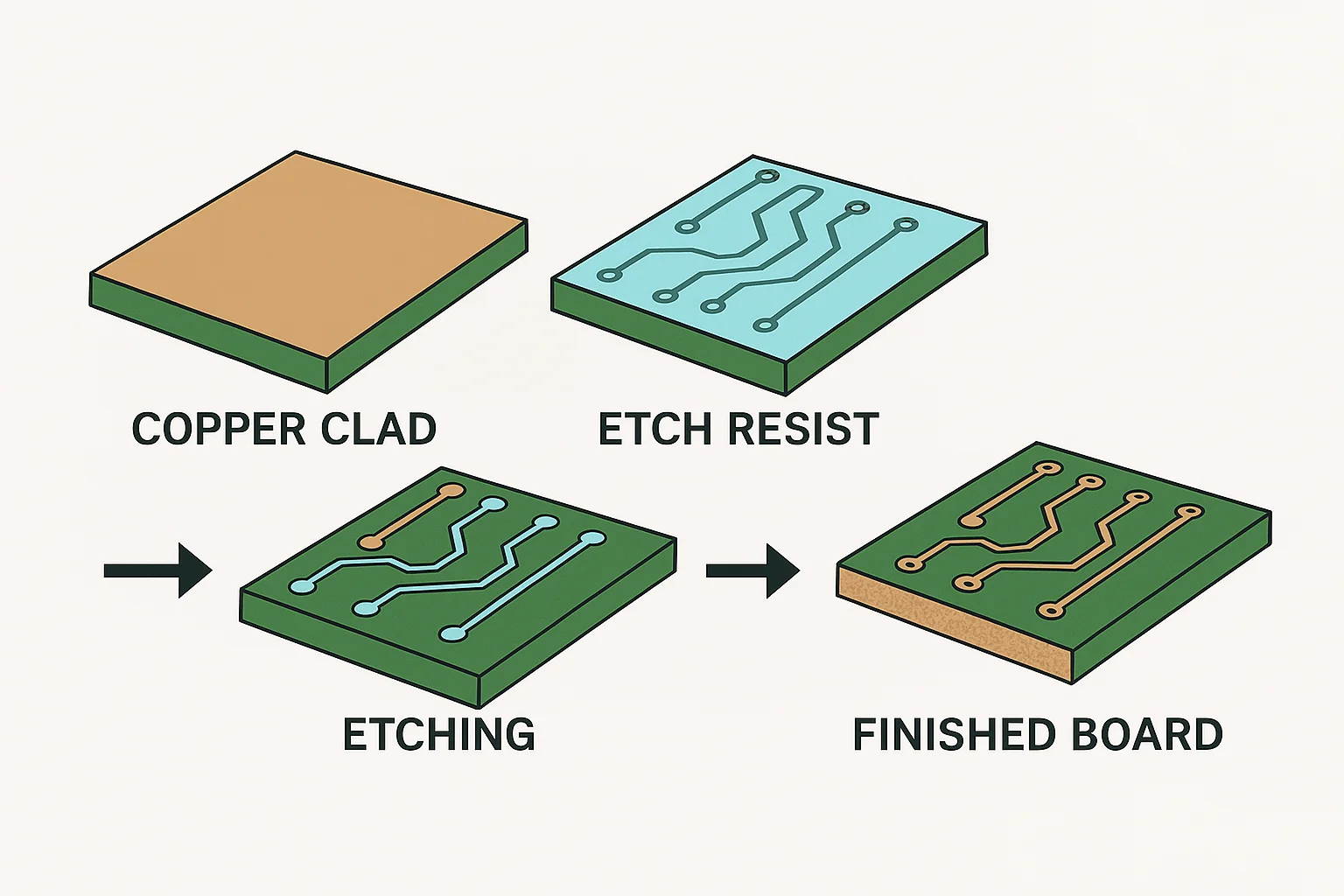

A Single Copper Layer Board, also known as a single-sided PCB, is the most fundamental type of printed circuit board. It consists of one conductive copper layer on one side of the board, while the opposite side is reserved for mounting components. This type of PCB is widely used in simple electronic devices due to its cost-effectiveness and ease of manufacturing. At Ittefaq Electrotech, we specialize in producing high-quality single copper layer boards tailored for reliable performance in everyday electronic applications.