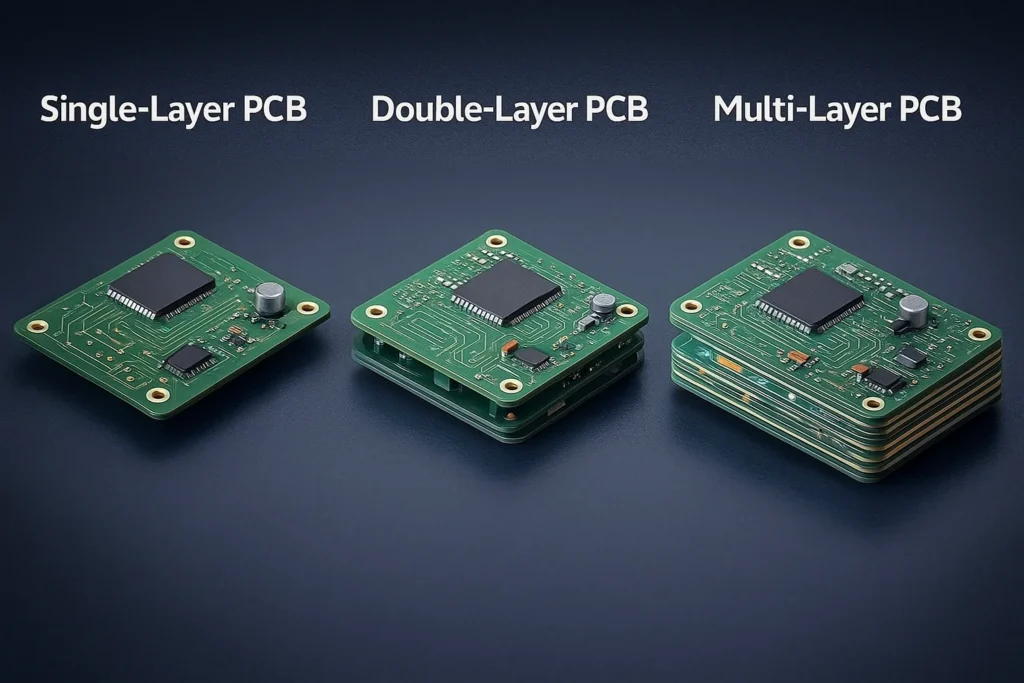

If you’re new to PCB design or manufacturing, understanding the difference between single-layer, double-layer, and multi-layer PCBs will help you choose the right option for your project.

1. Single-Layer PCBs

A single-layer PCB has just one copper layer on one side of the board.

The components and copper traces are placed on the same side, making it the simplest and most affordable type of PCB.

Where They’re Used

Calculators

Power supplies

Basic home appliances

LED lighting

Simple toys and gadgets

Why Choose Single-Layer?

Cheapest to manufacture

Easy to design

Good for low-complexity circuits

Limitations

Limited routing space

Not suitable for advanced or compact electronics

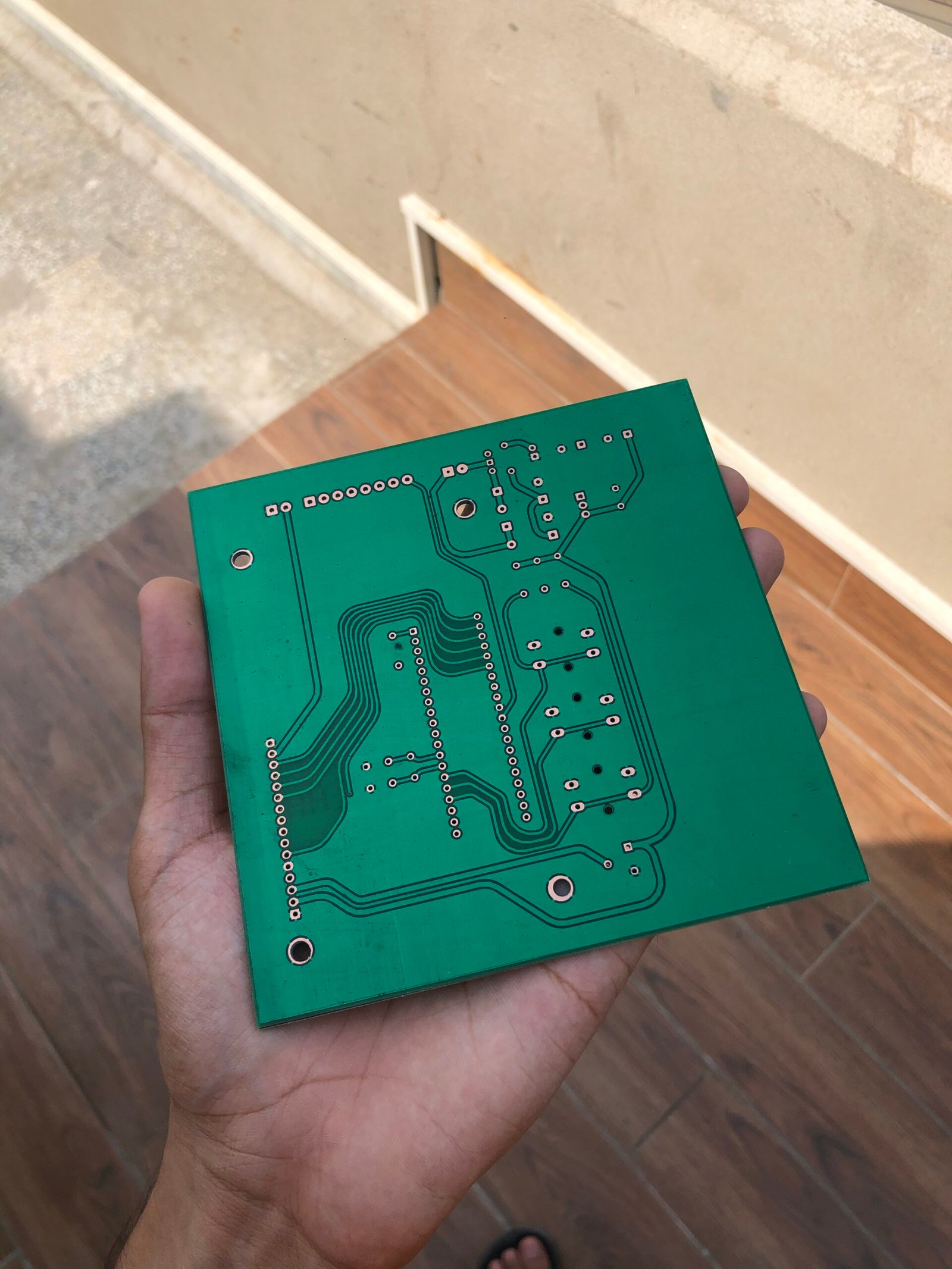

Get Your Single-Layer PCB Today

For high-quality single-layer PCBs that are reliable and cost-effective, trust itelectrotech for your PCB fabrication needs. Our expert team ensures fast delivery and excellent precision for every project.

2. Double-Layer PCBs

A double-layer PCB has copper on both sides of the board—top and bottom.

You can place components and route traces on both sides, which allows more complex and compact designs.

Where They’re Used

Consumer electronics

Power control devices

Industrial machines

Automotive electronics

Why Choose Double-Layer?

More routing flexibility

Handles moderate complexity circuits

Efficient use of space

Limitations

More expensive than single-layer

Still limited for very high-speed or dense circuits

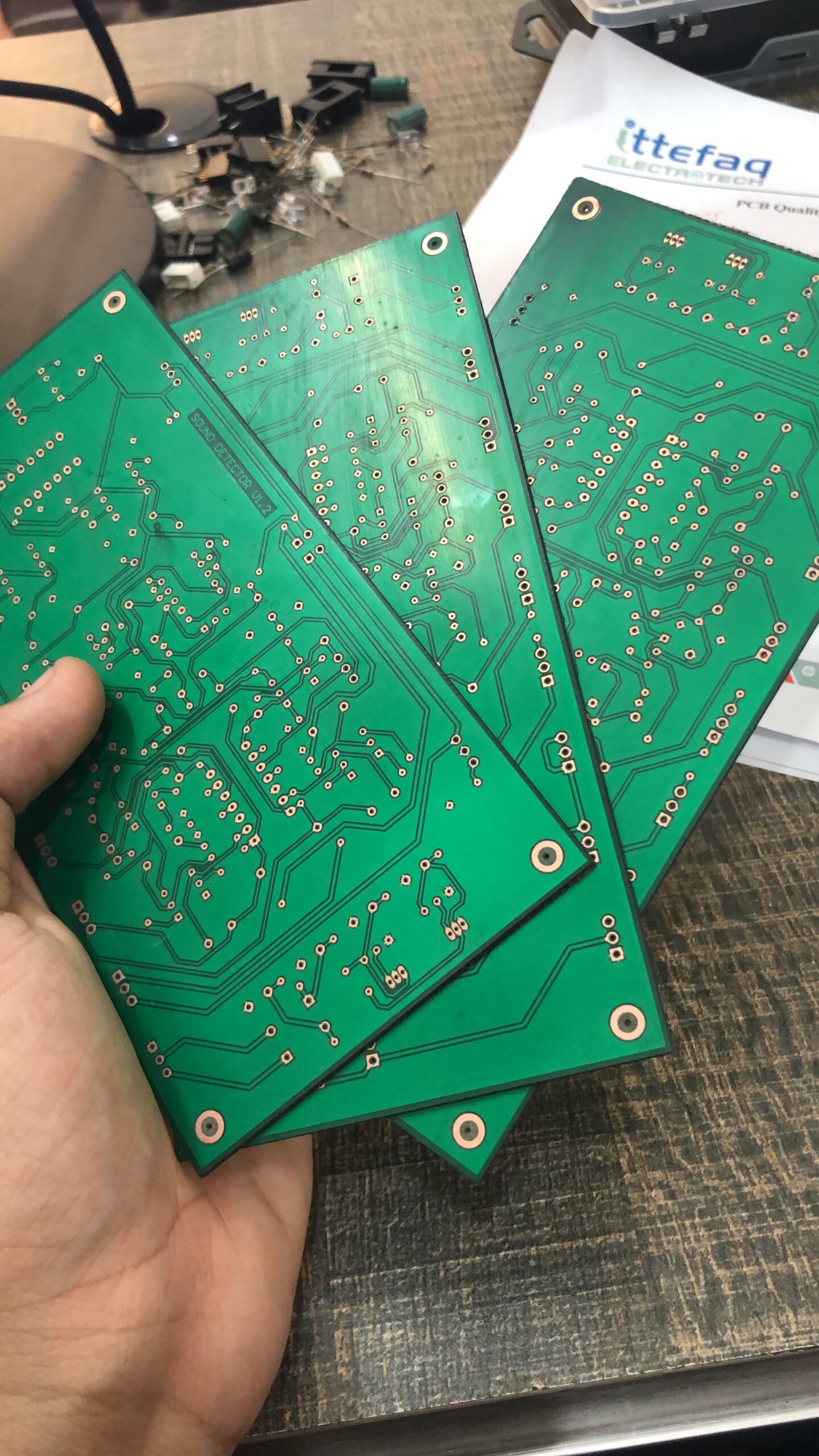

Bring Your Double-Layer PCB to Life

Looking for precise, reliable, and durable double-layer PCBs? itelectrotech provides top-quality fabrication with expert support, ensuring your projects meet high performance and quality standards.

3. Multi-Layer PCBs

A multi-layer PCB has three or more copper layers stacked together.

These layers are separated by insulation and connected through vias.

Multi-layer designs allow engineers to handle very complex, high-speed, and high-density circuits.

Where They’re Used

Smartphones

Laptops and tablets

Medical devices

Communication equipment

GPS and high-performance electronics

Automotive and aerospace systems

Why Choose Multi-Layer?

Extremely high circuit density

Excellent performance for advanced electronics

Better signal integrity and noise reduction

Supports high-speed data transfer

Limitations

Higher manufacturing cost

More complex to design

Longer production time

Conclusion

The number of layers in a PCB has a huge impact on performance and cost.

Single-layer boards are great for simple projects, double-layer boards balance complexity and affordability, and multi-layer boards power today’s most advanced devices.

See our PCB manufacturing expertise in action — check out our completed projects in our portfolio!