Here’s a clear, step-by-step explanation of how a PCB goes from concept to a finished product.

1. PCB Design and Schematic Creation

The process begins with an engineer creating a schematic diagram. This shows how all the electronic components connect to each other.

Once the schematic is ready, it’s converted into a PCB layout using design software. The layout defines:

Board dimensions

Component placement

Copper trace routing

Layer structure

When the design is finalized, Gerber files are generated—these files guide the manufacturer at every step.

2. Material Selection

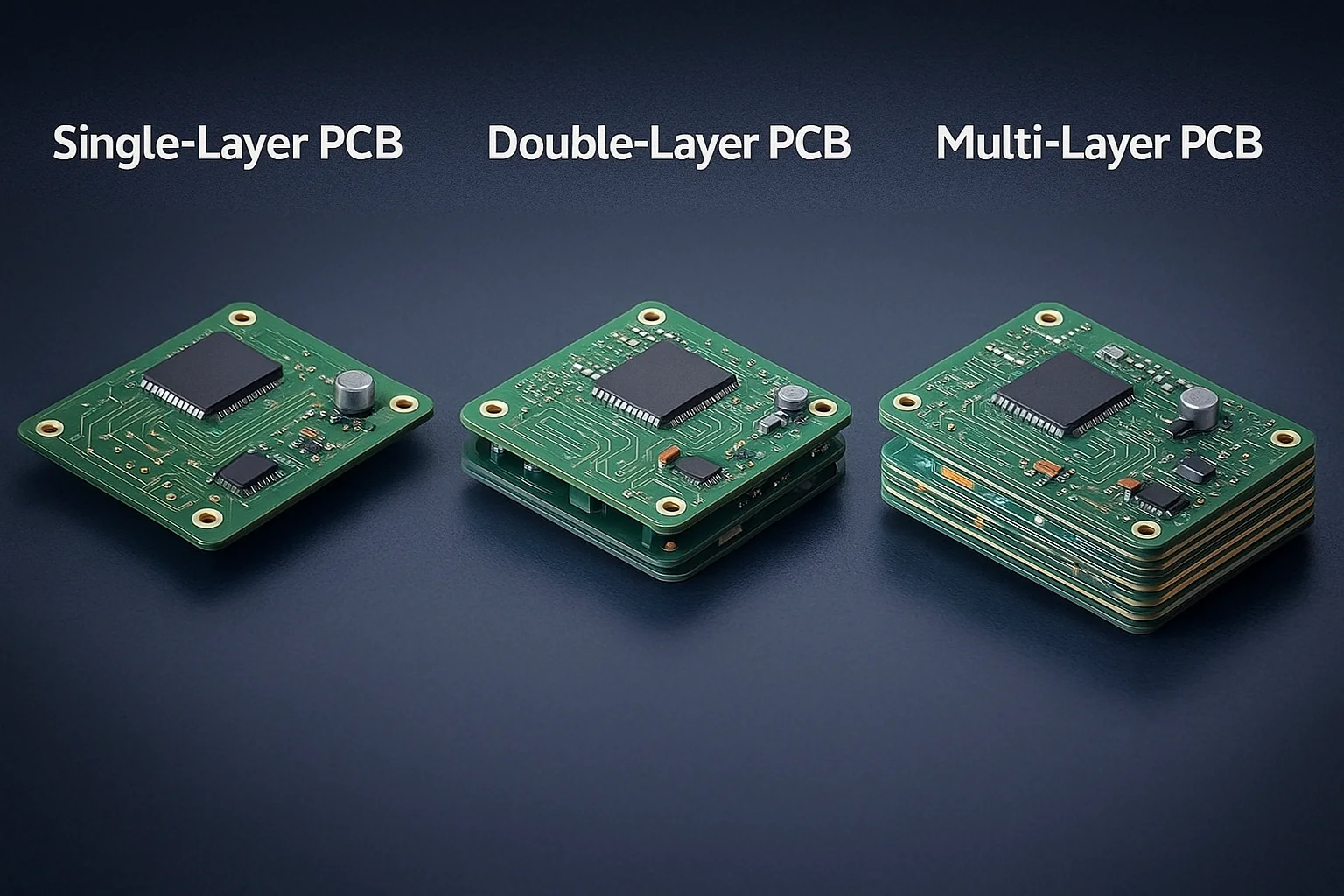

The base material, usually FR-4, provides strength, insulation, and heat resistance. Depending on the complexity, the PCB may be:

Single-layer

Double-layer

Multi-layer

Copper thickness and layer count are also decided at this stage.

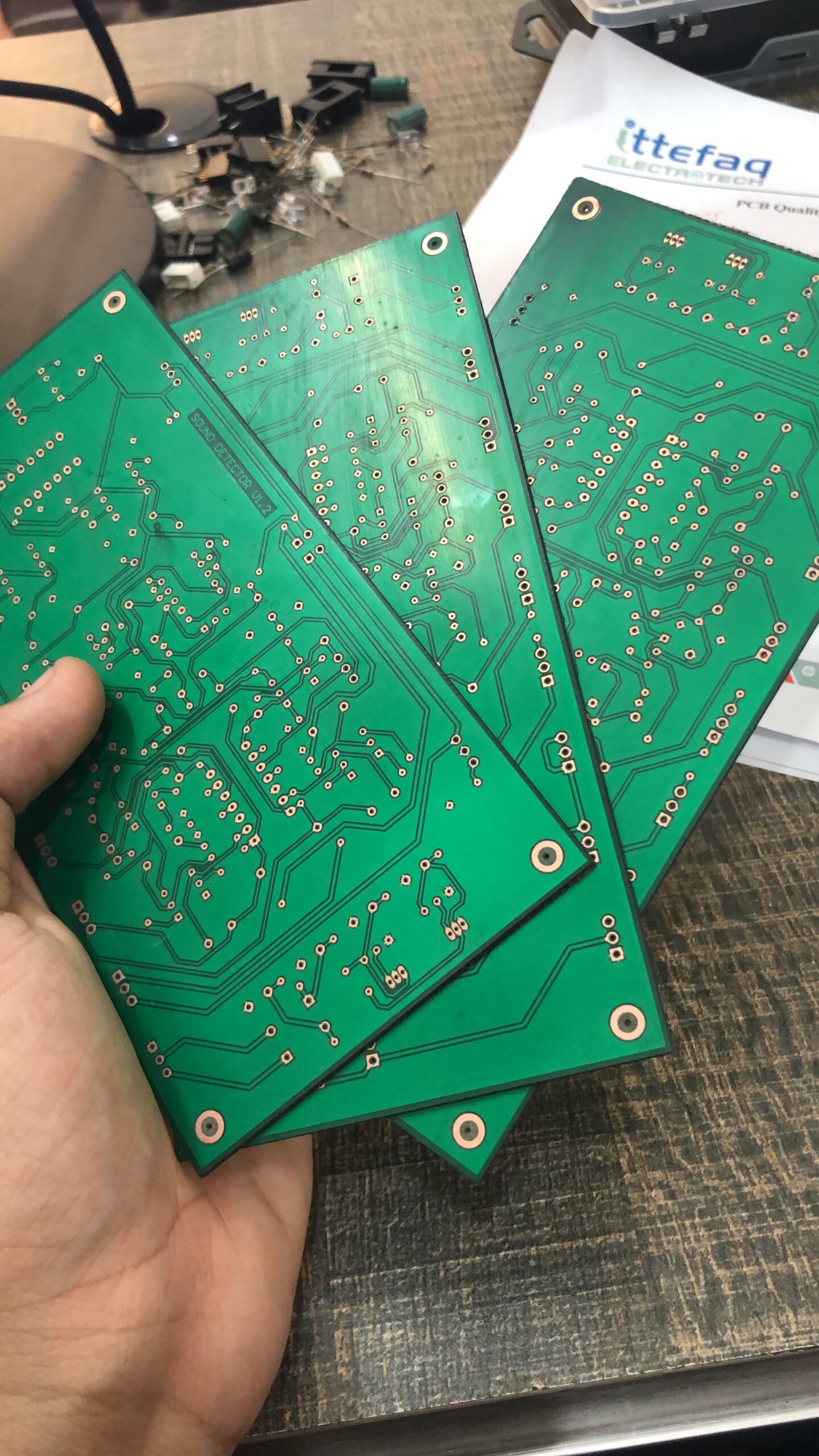

3. Printing the Circuit Pattern

The manufacturer transfers the PCB design onto the copper-clad board.

This is done using a photo-sensitive method, ensuring that the copper pattern matches the digital layout with high precision.

4. Etching the Copper

Next, unwanted copper is removed through an etching solution.

Only the copper that forms the circuit remains on the board.

This step defines the electrical pathways that carry signals and power.

5. Drilling Holes

Tiny holes are drilled for:

Component leads

Vias connecting different layers

Mounting points

Computer-controlled drilling machines ensure accuracy down to micrometers.

6. Plating and Layer Connection

For multi-layer and double-layer boards, the drilled holes are plated with copper.

This creates strong electrical connections between layers and ensures signal continuity across the board.

7. Applying the Solder Mask

The familiar green coating you see on most PCBs is the solder mask.

It protects copper traces, prevents accidental short circuits, and ensures clean soldering during assembly.

8. Silkscreen Printing

Labels, component markings, company logos, and test points are printed on the board.

This helps technicians assemble and troubleshoot the PCB later.

9. Surface Finishing

To prevent oxidation and improve solderability, a surface finish is applied to exposed pads.

Common finishes include:

HASL

ENIG (gold finish)

OSP

Immersion tin or silver

Each finish has different benefits depending on the device requirements.

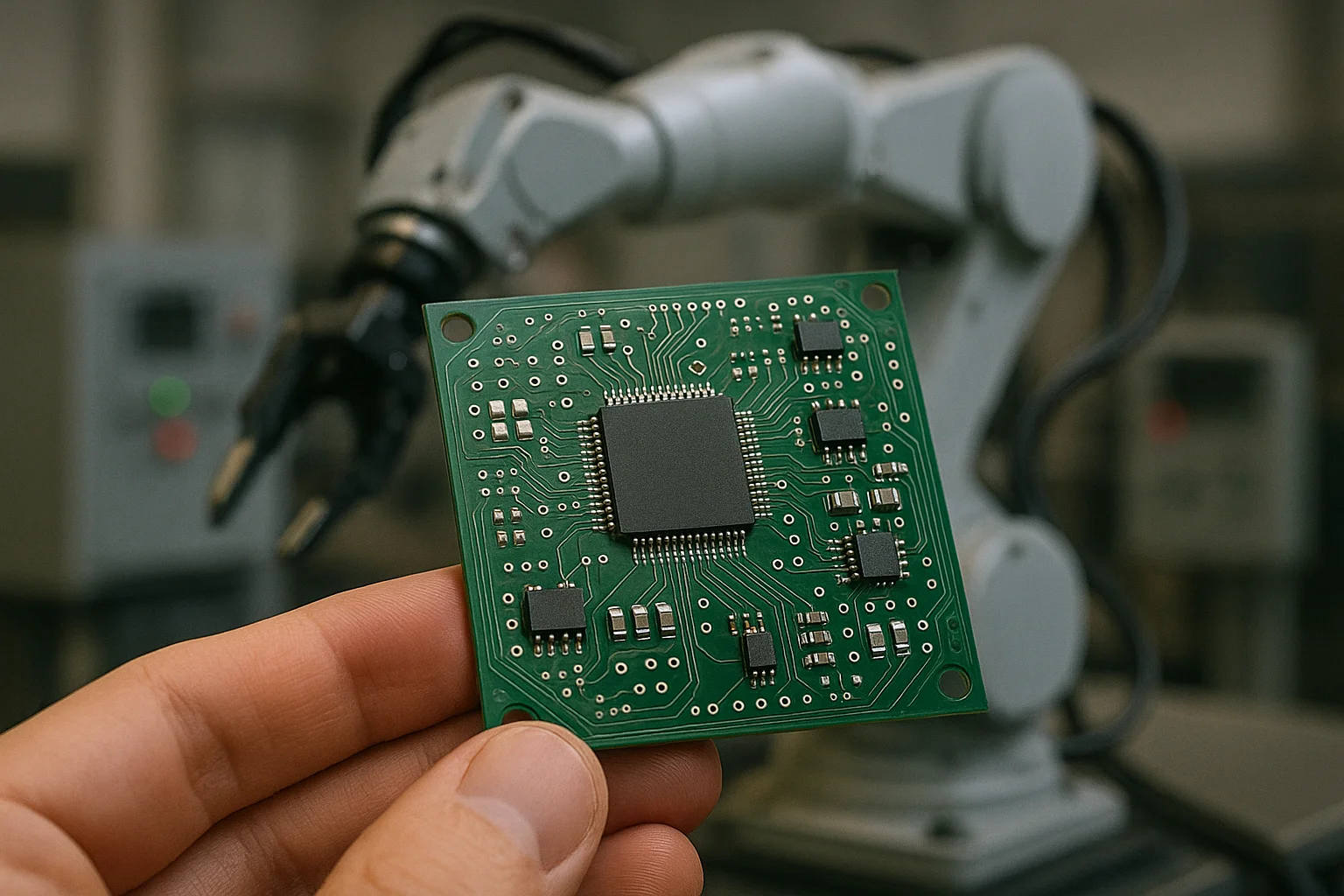

10. Inspection and Testing

Before the board is approved, it goes through strict quality checks such as:

Visual inspection

AOI (Automated Optical Inspection)

Electrical continuity testing

This ensures the PCB matches the design and performs exactly as intended.

11. Final Cutting and Packaging

The finished PCB is cut into its final shape, cleaned, and packaged safely for delivery—ready for assembly into an electronic product.

Conclusion

From designing the circuit to applying finishes and testing, PCB manufacturing is a precise process that blends engineering, technology, and craftsmanship. Understanding these steps helps you appreciate the care and expertise behind every board.